Explore our 360° facilities…

-

![Several large industrial machines in a high-bay facility.]()

Pilot-scale cathode synthesis

Lithium metal oxide cathode synthesis has been scaled up to 30 metric tons per year in our pilot plant, located in Rowley, MA.

-

![A series of blue enclosed automated machines in a modern, well-lit production facility.]()

Pilot-scale pouch cell production

Our state-of-the-art cell production line in Lexington, MA supports manufacturing throughput on the order of a megawatt-hour per year.

-

![Laboratory setup with four black box-shaped machines on a countertop.]()

Precursor & cathode synthesis

We can rapidly synthesize a wide range of Li-ion active materials in batches of a few grams to a few kilograms.

-

![A scientific instrument with multiple samples being analyzed.]()

Materials characterization

Materials characterization is carried out onsite using a wide range of custom-designed titrations as well as ICP-OES, XRD, BET, PSD, KF, TGA, DSC, and SEM with EDS.

-

![Close-up of coated foil passing around metal rollers.]()

Electrode coating

Double-sided electrode coatings of diverse chemistries and formulations can be applied at the pilot scale to demonstrate desired cell performance characteristics.

-

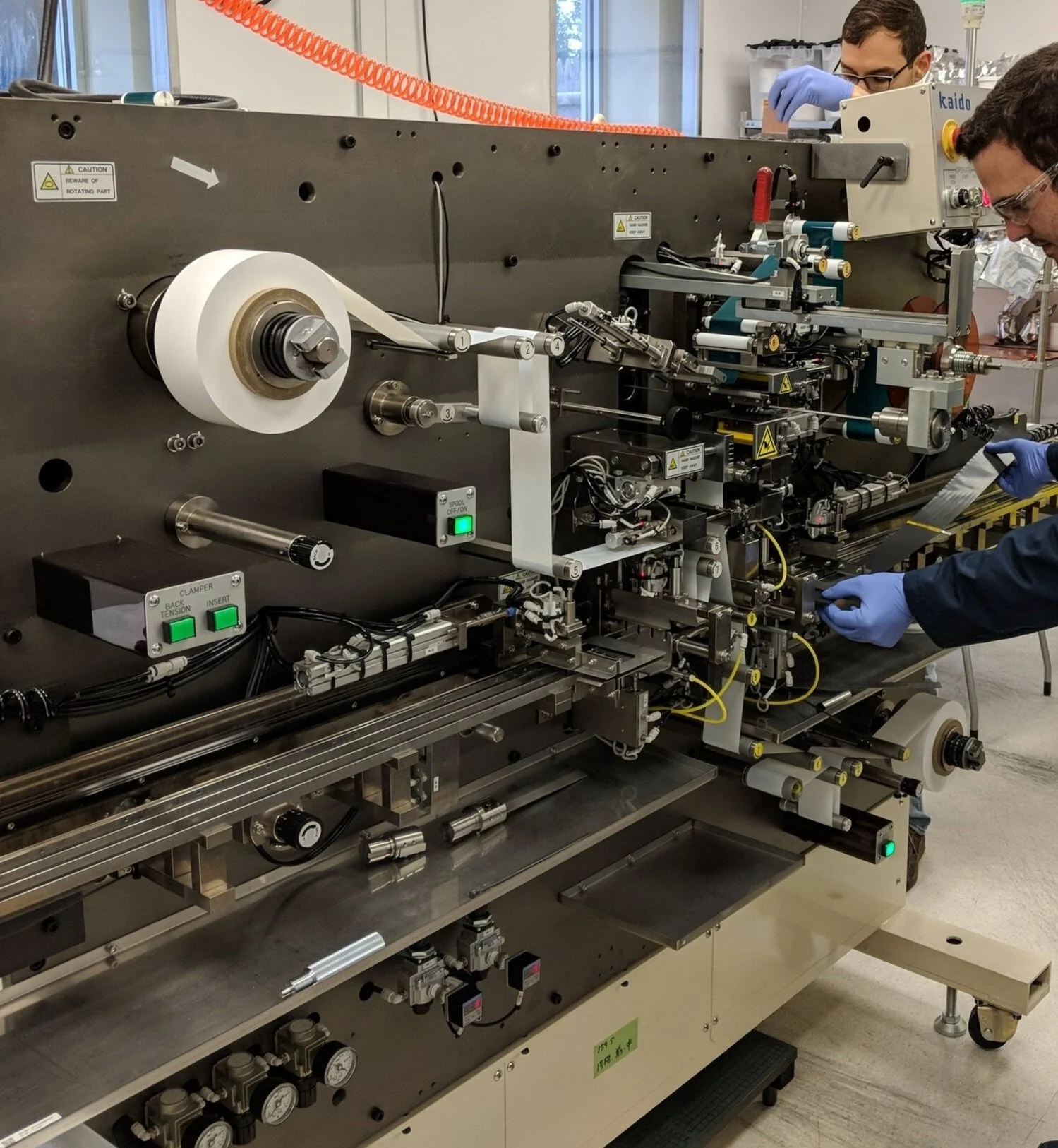

![Technicians in lab attire working on a large automated machine.]()

Prototype cell fabrication

Our battery prototyping facility enables rapid assembly of Li-ion cells, both cylindrical (18650) and pouch (up to 15 Ah, various form factors).

-

![Battery test equipment racks with numerous cables connected, and a computer monitor displaying data.]()

Electrochemical testing

With nearly 1000 cycler channels in-house, we can test a wide range of Li-ion cells and packs at ambient and extreme temperatures.

-

![A metal safety enclosure with a small, reinforced glass window and an open door revealing a battery crush fixture inside.]()

Abuse characterization

Abuse tolerance of multi-Ah Li-ion cells is characterized in-house using highly-instrumented custom test systems. Capabilities include nail penetration, hot box, impact, crush, overcharge, and external short circuit.

-

![A rectangular enclosure with transparent sides, showing battery pack and circuit boards inside.]()

Pack prototyping

Battery packs for specialized applications are designed, prototyped and tested in-house. Pack integration facilities include ultrasonic and spot welding equipment, as well as a fully equipped electronics lab.